Overhead line cover systems deliver a vital shield for power lines. These systems function to ensure the integrity of overhead conductors from environmental factors. They include various components, such as weatherproof enclosures, that minimize the risk of disruptions. Overhead line cover systems play a role to the performance of power grids by maintaining the safety and robustness of overhead lines.

- Advantages typically associated with overhead line cover systems encompass:

- Reduced maintenance costs

- Minimized risk of electric shock

- Improved weather resistance

Protecting Power Lines with Durable Covers

Power lines are crucial for our modern lifestyle, supplying electricity to homes and businesses. However, they are also vulnerable to destruction from a variety of elements. Weather events like storms and high winds can cause significant problems to power lines, leading to outages and safety hazards. To mitigate these risks, durable covers have become an essential measure. These covers provide a protective defense against the environmental challenges, helping to keep power lines functional and prevent costly repairs.

A well-designed cover can also reduce the risk of power surges. By protecting the wires from moisture, durable covers help to stop corrosion and other deterioration. Furthermore, they can enhance the appearance of power lines, blending them more seamlessly into the surrounding environment.

Ensuring Safety and Reliability Overhead Line Covers

In the realm of electrical infrastructure, ensuring safety and reliability is paramount. Overhead lines make up a critical component of power distribution networks, but they also pose potential hazards if not properly protected. This is where overhead line cover solutions come into play. These advanced coverings provide a crucial layer of defense against environmental factors such as weather, debris, and accidental contact. By safeguarding power cables, these covers minimize risks to personnel, property, and the overall integrity of the electrical grid.

- Overhead line covers are designed to withstand harsh climatic conditions, including extreme temperatures, UV radiation, and moisture.

- Created from durable materials, these covers provide a robust barrier against physical damage caused by falling objects or animals.

- Proper installation of overhead line covers improves the safety and reliability of power lines, reducing the risk of outages and equipment failure.

Elevated Protection for Overhead Electrical Infrastructure

Ensuring the reliability of overhead electrical infrastructure is paramount to maintaining a reliable power grid. Overhead lines are vulnerable to a variety of environmental factors and potential hazards, necessitating robust protection measures. Modern advancements in protective technology offer innovative ways to mitigate risks and ensure the integrity of overhead electrical systems. From advanced insulation materials to smart monitoring systems, these solutions are designed to prevent downtime, enhance safety, and maximize overall system performance.

Superior Design for Overhead Line Cover Applications

Designing efficiently overhead line covers involves a blend of factors to ensure both shielding and performance. Key considerations include the kind of conductor, environmental factors, anticipated loads, and regulatory standards.

A well-designed overhead line cover should minimize degradation from environmental conditions while providing adequate strength to withstand strain. The choice of material is crucial, with common options including plastics, aluminum, and hybrid designs.

In conclusion, the optimal design will be determined by a thorough assessment of the specific application demands. Consulting with experienced engineers and specialists in overhead line installation is highly advised to ensure a safe and functional outcome.

Effective Line Cover Installation and Care

Achieving a long-lasting and robust line cover installation hinges on meticulous planning and diligent execution. Before commencing the installation process, it is crucial to carefully assess the site conditions and select an appropriate type of line cover that is compatible with the underlying infrastructure and the anticipated load. Verify that all necessary equipment and tools are readily available, including trenchers, backhoes, compaction equipment, and a reliable measuring system.

During the installation phase, meticulous attention should be given to ensuring proper depth and alignment of the line cover. Compaction should be executed thoroughly across the entire installation area to achieve optimal stability and prevent future settlement or displacement. Regular inspections are essential for detecting any potential issues such as cracks, moves, or signs of erosion. Prompt corrective measures should be taken to address these concerns before they escalate into major problems.

- Scheduled inspections can encompass visual assessments of the line cover's integrity, checking for any damage or deterioration.

- Seasonal testing of the backfill material's compaction levels can verify that the installation remains stable over time.

Maintaining a comprehensive maintenance log that documents all inspections, repairs, and replacement activities is crucial for tracking the line cover's performance and identifying any recurring issues. By adhering to these guidelines, you can enhance the click here lifespan and effectiveness of your line cover installation, ensuring the continued integrity and functionality of your underground infrastructure.

Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Sydney Simpson Then & Now!

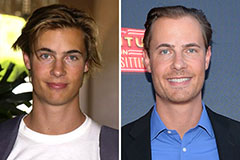

Sydney Simpson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Kane Then & Now!

Kane Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!